Bite-Super is a company specializing in the R&D, production and manufacturing of thermoelectric TECs, and is committed to providing good TEC products and services to the communication, optoelectronics, industrial laser, medical and other industries.

Last year we had interviewed Bite-Super, after several appointments, this week finally caught up with the opportunity, in Bite-Super Xi'an operation center, I had the honor to interview Mr. Shi Chaopeng, general manager of Bite-Super, also the founder of Bite-Super, after about a year's time, to learn about our and the industry's most concerned about the issue: the current status of the product and the industry's most concerned about the issue: Bite-Super's product and the current status of the product. -Super's product status and commercialization.

Aiming at Micro TEC industry, overcoming material and process difficulties

Mr. Shi has held key positions at Laird and Marlow, the world's leading TEC companies in the UK and the US, and has also worked closely with well-known TEC companies in Russia. He has more than 20 years of technical and marketing experience in the TEC field. During his 20 years in the industry, the MicroTEC market has been monopolized by foreign brands, and domestic customers can only choose from a few European, American and Japanese brands when looking for such suppliers. After leaving the U.S. company, Mr. Shi keenly saw that the MicroTEC industry, like many high-tech products, conforms to the law that the early European, American and Japanese companies dominate the market for several years, and then Chinese companies take over, similar to industries such as laser chips, automobiles, high-speed rail, etc. In his insight into this general trend, Mr. Shi realized that the MicroTEC market was dominated by foreign brands for over 20 years. With the insight of this trend, Mr. Shi determined to target MicroTEC industry, close to the needs of domestic customers, and committed to provide domestic optical communication enterprises with home-made solutions, reversing the passive situation of relying on European, American and Japanese companies.

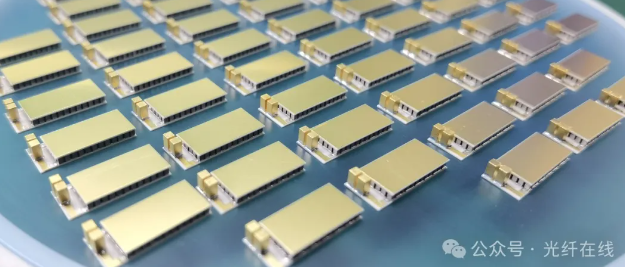

There are two main difficulties in the R&D and production of MicroTEC, one is the material and the other is the process. Bismuth telluride as the core of thermoelectric materials, has been the main half a century, and can be mass-produced mainstream materials, its accessibility has been extremely wide. The key to success or failure is to overcome the process difficulties. By the end of 2021, Mr. Shi's team gradually overcame the process difficulties, and the process met MicroTEC's needs in three dimensions: production automation, quality visualization, and cost optimization. Thus, Bite-Super (Shenzhen) Co., Ltd. was born in Shenzhen. At the same time, Bite-Super mass production base was also established in Xi'an. Today, Bismuth Sheng Xi'an MicroTEC has a monthly production capacity of more than 300Kpcs and an annual production capacity of more than 4 million pcs.

Realizing the three goals of TEC: impeccable reliability, mass delivery, and exceeding customer's expectation on price.

“To be a TEC, our advantage is that we understand customers' needs and it is easier to be in the same frequency with them.” Mr. Shi said, “When we first decided to do TEC, we set ourselves three goals: impeccable reliability, volume delivery, and exceeding customer expectations of price, i.e., to provide the industry with ‘faster, better, and more cost-effective’ TEC, and so far, all three goals have been achieved. “

TEC products are particularly small in size, and their internal crystals are even smaller, down to 0.15mm*0.15mm. there is no way to accomplish mass assembly production and ensure stable supply under mass production without a process of excellence. Bite-Super has developed its own TEMAR (Thermo Electric Module Asssembly Robot) for MicroTEC assembly, which integrates AOI function. The integrated AOI function ensures that each crystal is thoroughly inspected before mounting, and it is capable of mounting each crystal to the circuit with stability, efficiency and precision. Each TEMAR is equipped with eight lenses and four linear moving robotic arms, and the placement efficiency is 5 times higher than the traditional D/B. Bite-Super has also developed other unique TEC-specific processes, such as auto-soldering machines, auto-posting, and auto-inspection of ACR machines, etc. The combination of these automated processes ensures that each crystal is fully inspected before placement. The combination of these automated processes ensures efficient and stable output.

In optical modules, TEC is the second most important device after lasers. Mr. Shi told the editor, “TEC is in the upstream of the industry chain, and its reliability will affect the midstream optical modules, and then affect the downstream communication equipment. Product reliability is the foundation of Bite-Super. After the establishment of the company, we started to submit samples to customers only after seven or eight months and four or five rounds of reliability verification, and Bite-Super's quality team conducts On-going Reliability Testing every week, and the data has been stable from April 2022 to now, and the resistance variation rate has been within 1.5% for a long time.” Mr. Shi told the editor, ”TEC is in the upstream of the industry chain, and its reliability will affect the midstream optical modules, which will in turn affect the downstream communication equipment. “

TEC production involves electroplating process, which is a highly polluting process and is basically outsourced to supporting companies in the industry. Although the cost of this piece is not big, but it is one of the key processes of product performance, which is related to the stability and reliability of the product, Bite-Super has planned to take this process into their own hands, and has already selected sites around Xi'an. It is expected that the electroplating production line will be established this year, which will ensure that the surface treatment process of TEC can be independently controlled and the flexibility of production delivery.

As Mr. Shi mentioned before, their advantage lies in knowing what customers think and understanding what customers think. Bismuth Sheng has always regarded itself as the supernumerary TEC R&D team of customers, providing customers with personalized technical support and product design. The competition in the market is ultimately the competition of service + cost performance. Over the past year, Bismuth Sheng has been given the opportunity to compete with European and American counterparts in several projects, in which Bismuth Sheng has optimized the performance of its products through design, which is not inferior to foreign counterparts, and its energy-efficiency ratio is higher than that of its counterparts both at home and abroad.

Stick to “Honesty、Guanghui” to meet the future opportunities

In the early stage of its establishment, Bite-Super invested a lot of time and energy to solve the material and process problems of TEC, and didn't let the product go to the customers until October 22, 2022, which is the first year of Bismuth Sheng's products, and the shipment volume of that year reached several tens of thousands of pieces in total. Mr. Shi told the editor that as a startup, Bite-Super focuses on the present and looks to the future, maintains its strategic determination and patience, adheres to the value of “honesty and broad benefits”, and gradually provides valuable products and services to each customer. Up to now, Bite-Super has accumulated nearly 70 customers, and has provided stable TEC products to more than 30 of them.

Under the wave of AI, the optical module industry is experiencing unprecedented growth, Mr. Shi said that there are both challenges and opportunities, and Bismuth Sheng Semi-Conductor is ready to supply stable and cost-effective TEC products to the market in large quantities. Of course, along with the development of liquid-cooled optical modules and silicon optical modules, the TEC market may also be affected in the future. As part of the longer-term plan, Bite-Super has started to plan additional products with TEC as the core under the premise of doing a good job with TEC, such as temperature control modules in the automotive field, cooling solutions for fast charging of new energy batteries, and energy harvesting solutions utilizing the principle of generating electricity by the difference in temperature, etc. According to Mr. Shi, these TEC products with high added-value are expected to be available to the market in succession by the year 2025. According to Mr. Shi, these high value-added TEC products are expected to be launched in 2025.

Conclusion

Nothing is impossible to a willing heart. We have reason to believe that Bite-Super will be able to add bricks and mortar to the development of the industry, and contribute its unique value to all related fields.